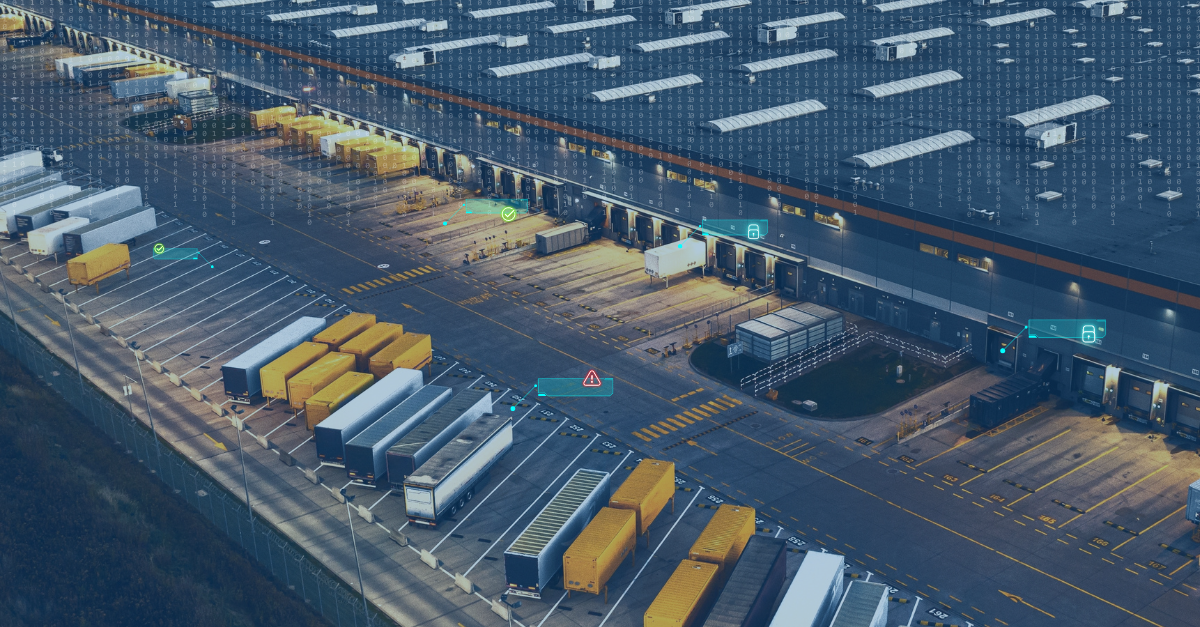

It seems that yard management, while a critical component of the overall supply chain, doesn’t get the attention or investment it deserves compared to warehouse and transportation operations. But it’s no less important in terms of keeping the line moving with shipping, production, fulfillment, and inventory management.

Yard management — gate operations, asset management, storage and drop zones, and dock scheduling — requires a high degree of logistical precision and coordination in order to run efficiently. However, if operational hurdles are not addressed in the yard, they quickly impact upstream and downstream functions. Schedules without much margin of error are thrown out of kilter, time and money are wasted, and customers and partners are unhappy.

Let’s look at the roles within yard management, some common challenges faced by operations teams, and solutions that can improve efficiency and operational flow.

Key Functions Within Yard Management

Gate operations have been a largely manual process of vetting vehicles and personnel entering and exiting a facility. It requires coordination among personnel to ensure smooth vehicle entry and exit. Gate operations are also responsible for managing traffic flow within the facility grounds.

Asset management involves maintaining the inventory of all yard assets (trailers, containers, yard trucks, forklifts, etc.) and their locations. Its role is to make sure every item is accounted for and available when needed, while maintaining security and minimizing damage.

Drop zones are overseen by yard managers or supervisors, assisted by yard jockeys and spotters. They’re responsible for maximizing asset utilization and movement — for instance, from a storage location to a loading dock.

Dock scheduling involves coordinating dock assignments for inbound and outbound shipments. Its role is to ensure that loading/unloading goes smoothly and with minimal delays, reducing congestion and optimizing asset use (docks, personnel, and equipment).

Common Operational Hurdles in Yard Management

The use of legacy systems and manual processes, still prevalent in yard management today, leads to errors and delays. This can increase labor costs and reduce responsiveness, impacting efficiency and customer satisfaction.

Lack of Real-Time Visibility

Manual tracking of asset movements severely limits visibility into yard operations. Without access to real-time information, delays proliferate as staff struggles to locate trailers, chassis, and containers.

This hampers the ability of yard managers to make timely decisions, leading to slower response times in locating misplaced trailers or handling unexpected delays. Poor visibility also makes it harder to efficiently allocate yard personnel and equipment, resulting in underutilization or overuse of assets.

Inefficient Gate and Dock Management

This creates significant operational challenges, resulting in trucks waiting unnecessarily due to overbooking or underutilization of dock space. Gate management issues such as delays in processing or poor gate assignments further compound the issue. The result is an overall increase in wait times, delays in loading and unloading, higher operating costs, and decreased productivity.

Poor Communication and Coordination

Poor communication among yard staff, drivers, and warehouse personnel leads to bottlenecks in yard operations. When teams don’t share timely information or coordinate properly, it can result in confusion over trailer locations and dock appointments and inefficient yard movements. This lack of coordination reduces yard throughput, increases dwell times, and negatively impacts driver satisfaction.

Tactics for Overcoming Yard Management Challenges

Given the number of issues that can plague legacy yard operations, managers need assistance from cutting-edge technology in order to improve performance and eliminate inefficiencies.

AI-Enhanced YMS

Artificial intelligence (AI) and machine learning (ML) are being leveraged to augment existing yard management systems (YMS) and bring greater efficiency. This includes using predictive analytics to review data from live camera feeds, assess situations, and offer solutions.

For instance, algorithms can be used to analyze historical data, real-time information, and external factors to identify chokepoints and resource requirements. These insights empower yard managers to proactively allocate resources where and when needed.

AI also provides real-time visibility into various aspects of yard operations, including the location and status/availability of all yard assets. This information can be accessed by yard personnel, reducing the risk of errors and delays.

Optimized Dock and Gate Scheduling

An AI-enhanced YMS with yard vision capabilities can automate operations from the gate to the loading docks. Capturing dozens of vehicle elements via optical character recognition (OCR) speeds up verification for faster gate access. Also, all yard assets are automatically tracked and managed, making location and access quicker and smoother.

With an optimized vehicle flow, trucks, and trailers are quickly routed to the proper dock for unloading and loading. This keeps shipment schedules on track, reducing the need for costly expedited delivery.

Enhanced Communication and Coordination

Effective communication among staff, carriers, and drivers is crucial for smooth yard operations. Regular training and briefings ensure that staff are well-informed and equipped to handle their tasks effectively.

Clear communication channels, including real-time updates for partners, enhance coordination and reduce delays. This kind of close collaboration facilitates smoother yard operations, helping manage expectations and reducing wait times.

Don’t Trust Yard Management Efficiency to Legacy Tools and Processes

Addressing inefficiencies in yard operations (poor communication, outdated processes, inadequate dock and gate management) improves efficiency and reduces costs. By leveraging modern technology like yard vision systems and fostering better coordination among teams, yard managers can see increased performance and throughput.

EAIGLE, a leader in AI-driven yard operations technology, offers an innovative yard vision system that delivers significant efficiency gains from the gate to the dock. EAIGLE analyzes real-time data from a facility’s cameras via optical character recognition (OCR) to automate gate access, reducing delays and costs. It can also optimize yard routing and dock scheduling, as well as pinpoint the location and status of all assets.

An enhancement rather than a replacement of YMS, EAIGLE powers yard vision for leading players like FourKites and C3. To learn more about how EAIGLE can transform your yard operations, request a demo.