For years, yard management was the operations stepchild in terms of available technology or investment. The warehouse management system (WMS) continued to evolve and expand its capabilities, and transportation management systems (TMS) handle routing, rate shopping, and load management functions.

Yard operations, despite its critical role in the supply chain, largely remained an also-ran in terms of digital maturity. Yes, there have been yard management systems (YMS) for years, and the technology has advanced, but the adoption rate has stalled in the high single digits. In addition, the kind of real-time visibility enabled by artificial intelligence (AI) is often not present in a standard YMS.

But now, the marriage of AI and optical character recognition (OCR) is opening up whole new possibilities for automating and optimizing yard management. These capabilities, which can be easily integrated with an existing YMS, improve efficiency and accuracy and reduce operational costs.

Understanding OCR Technology

OCR technology has come a long way since its inception in the early 20th century. The first OCR systems were developed in the 1920s and 1930s for reading printed text and telegraphy. The technology saw significant improvements in the 1970s with the advent of digital scanners and the development of algorithms for character recognition.

In the 1990s, the introduction of neural networks and machine learning (ML) techniques led to substantial improvements in the accuracy of OCR systems. The most recent advances have incorporated deep learning and natural language processing (NLP) through AI, enabling OCR systems to handle a wider variety of fonts, character styles, and languages with a greater degree of precision.

Key Components of OCR

Image pre-processing: This involves preparing the scanned image for analysis by improving its quality through noise reduction, binarization (converting to black and white), and skew correction.

Character recognition: This is the core component where OCR software analyzes character shapes within the image. It then matches them to a database of character patterns using pattern recognition and ML algorithms.

Post-processing: After characters are recognized, the system corrects errors, organizes recognized characters into meaningful formats, and sometimes leverages dictionaries or linguistic rules to improve accuracy.

Output formatting: The final recognized text is then outputted in a usable format, such as plain text, searchable PDFs, or editable documents.

These components work together to transform static text images into dynamic, usable data. This significantly enhances the efficiency of document management and information retrieval processes.

Challenges in Traditional Yard Management

Consider the implications of a manual yard operations process at a warehouse or manufacturing facility. The team is charged with orchestrating the flow of incoming trucks to available bays for loading and unloading. This includes overseeing asset staging and availability (trucks, trailers, containers, and chassis). Third-party carriers add a degree of variability in the mix of scheduling deliveries and outbound transportation.

All aspects of people, processes, and technology are in play. Data needs to be shared between yard operations, fulfillment, and transportation teams. Managers match production to available trucking capacity (internal and external), determine the need for yard assets, and project inbound/outbound volume. The aim is to create a smooth logistics flow, minimizing delays and maintaining production and order throughput. But fluctuations in demand and transportation capacity increase complexity yet again.

Without the ability to access real-time data for asset tracking, things can break down quickly. Often, inbound trucks are held up at the gate in a manual process, which can cause delays of 20 minutes or more per vehicle. This affects overall efficiency across operations, pushing up costs and increasing carbon emissions from idling trucks, an increasing target of sustainability regulations.

A manual process can also lead to mismatches in loading dock availability, causing significant delays per vehicle. Drivers are unable to find their assigned spots due to existing occupancy or congestion, and dropped trailers can’t be located quickly. This can slow outbound shipments, increase processing time for inbound freight, and adversely affect inventory management. Costs mount as yard workers hunt down trucks and trailers. Ultimately, production and order processing are affected, disappointing customers and partners.

A legacy YMS is definitely an improvement over a manual process that relies on log files and spreadsheets. But without the real-time visibility of systems with AI and OCR capabilities, asset tracking, routing, and scheduling are not optimized. This is because a legacy YMS lacks the ability to power dynamic decision-making. There are still delays, higher operational costs, and reduced productivity due to an inability to quickly adapt to changing conditions.

Applications of OCR in Yard Management

The introduction of OCR into yard management has led to a quantum leap forward in terms of capabilities for real-time asset identification and tracking.

Take, for instance, the mixed bag of standardization in logistics assets. Containers in 20-foot, 40-foot, and 45-foot configurations are highly standardized. This traces back to the 1950s and trucker Malcolm McLean’s vision for cargo container uniformity, which led to an ISO standard that transformed the world of logistics.

Chassis are also generally standardized in 20-foot, 40-foot, and 45-foot configurations as they transport containers in intermodal freight. However, there are also specialized chassis designed for tankers, as well as a low bed, gooseneck, and extensible chassis.

Dry van trailers are uniform at 48-foot or 53-foot configurations, based on U.S. and European standards. But many other types of trailers are non-standard: drop deck, double drop, lowboy, Conestoga, etc. Trucks, of course, are far from standardized, coming in many different sizes and dimensions.

This variety of asset types and dimensions, along with partial standardization, presents several challenges for a legacy YMS. For one thing, each has its own specific handling and storage requirements, complicating tracking and organization within the yard. This requires the use of adaptable storage solutions and adjustments to yard layout to accommodate them and prevent bottlenecks.

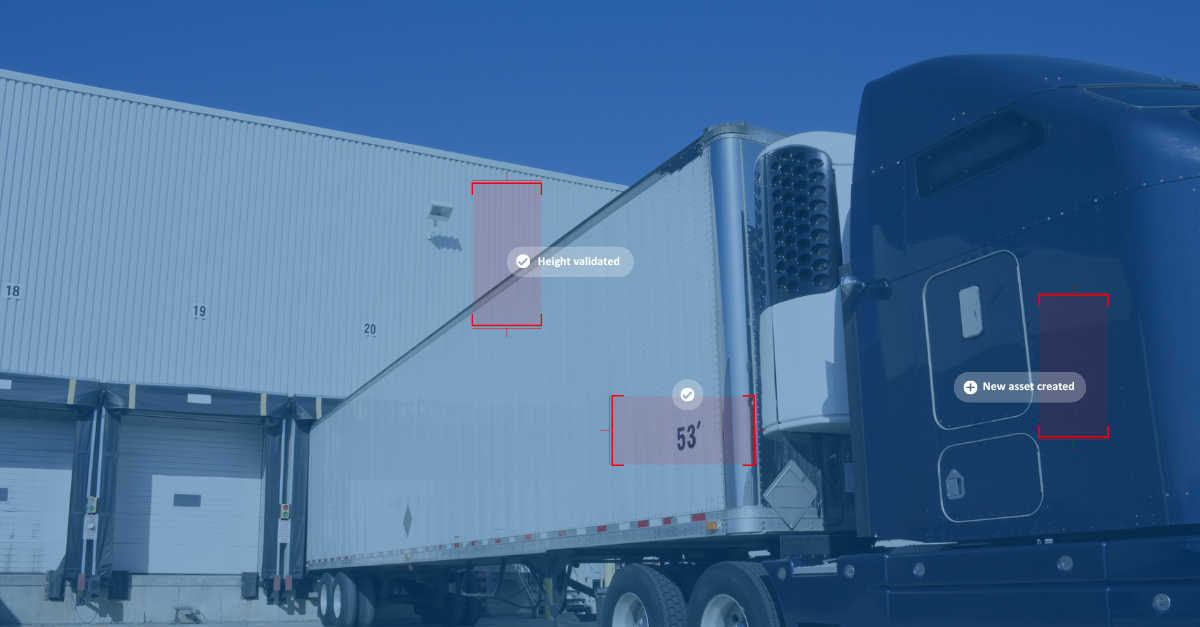

However, advanced yard operations software equipped with OCR and powered by AI can capture and decipher a number of unique asset identifiers across asset types, sizes, and configurations. This includes truck, trailer, chassis, and container numbers, US DOT numbers, and license plates.

AI-driven yard operations software with OCR technology takes capabilities and possibilities to an entirely new level. This has benefits not only for vehicle access control (VAC) and gate security, but throughout the yard for asset tracking and location, and optimized traffic flow to and from loading docks.

Benefits of OCR in Yard Management

Advanced VAC systems powered by AI and data analytics capture vehicle data through security cameras. OCR technology automatically identifies and records identifiers of logistics assets as they enter and move through the yard. This enables precise, real-time tracking of location and activity, streamlines traffic flow, and optimizes space utilization. It also means a reduction in errors from manual data entry. Gate access functions can be automated, speeding up vehicle and driver verification, eliminating backups, and reducing reliance on personnel.

Predictive management and planning via advanced analytics are also enabled. By accessing real-time data from OCR, AI analyzes historical and current vehicle movement patterns to predict traffic and storage needs. You can preemptively reallocate resources and adjust schedules to avoid yard congestion.

Benefits include improved decision-making through real-time data analytics and insights. Yard operations managers can improve space utilization, as the system directs vehicles to dock bays and storage areas based on current capacity and scheduled arrivals. The system can also proactive sense and avert bottlenecks through predictive traffic management.

Using OCR technology in yard management not only adds precision to vehicle tracking and data capture but also makes overall operations more efficient and responsive. Labor costs are reduced, and overall efficiency is improved.

Implementing OCR in Yard Management

Integrating OCR technology into an existing YMS involves several key steps. Thorough assessment and planning are needed to evaluate YMS capabilities and identify where and how OCR can enhance efficiency. Begin with a pilot program to test the integration with other systems (YMS, WMS, TMS), to ensure it meets your operational requirements before scaling up. Training staff on new processes and providing ongoing support is essential to a successful implementation.

When selecting a yard operations software solution with OCR, compatibility with your existing YMS and hardware and the scalability to handle increasing volumes are crucial. Adoption challenges such as data accuracy can be addressed through quality control measures. Provide comprehensive training that highlights the benefits and ease of use to gain staff buy-in. Resolve any technical issues promptly through close collaboration between your implementation team and the vendor.

Don’t Trust Your Critical Yard Functions to Manual Processes or Outdated Systems

Considering the importance of yard operations as a crucial link in the supply chain, manual processes just aren’t going to cut it anymore. To maintain gate security, ensure a smooth flow into and through the facility, and track various logistics assets, the latest technology needs to be put into play.

Without real-time visibility made possible by AI and OCR, yard tracking, routing, and scheduling are prone to errors and delays. A legacy YMS, while an improvement over manual processes, doesn’t have the capability to truly optimize all these functions. The result is delays, higher costs, and reduced productivity.

EAIGLE is a pioneer in applying AI to logistics. Its innovative OCR technology is a key component of its gate management (AVAC™ – Automated Vehicle Access Control) and yard operations (YardSight™) solutions. Both capture data from security cameras to optimize vehicle flow and manage yard assets. Importantly, EAIGLE’s platform augments rather than replaces a legacy YMS. EAIGLE improves operations by optimizing gate access, dock scheduling, and yard asset management. To find out more, request a demo today.